Control

To ensure the quality of the protective coating, a multi-step quality control process is implemented.

visual inspections

dimensional control

electrostatic control

The application of the coating is monitored through an internal control system, encompassing essential inspections such as visual inspection and holyday detaction. Visual inspection is conducted post-shot blasting, adhering to NACE Standard No. 1/SSPC-SP 5 and NACE SP0287, to assess the surface condition. Following the coating and curing stage, a comprehensive inspection utilizing CCTV and lance-mounted camera is employed, capturing frontal images and generating a detailed map of any existing imperfections.

To ensure mechanical integrity and longevity, multiple tube inspections are conducted, during production focusing on paint adhesion and durability. The process incorporates control systems designed to guarantee precise coating application.

In-line control and inspection of coating

Holiday inspection

Holiday inspection

Visual inspection

Visual inspection

After cleaning & coating

After cleaning & coating

Inspection equipment

Quality Inspection

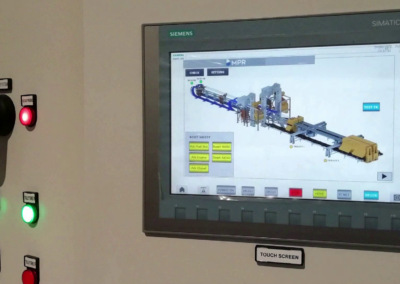

Our team guarantees precise coating application by integrating a control system into our machinery, ensuring accuracy and maintaining high quality throughout the entire coating process.

Control software

Our machinery are top-notch technology for an integrated and automatic line where steel need to be protect.