Cleaning

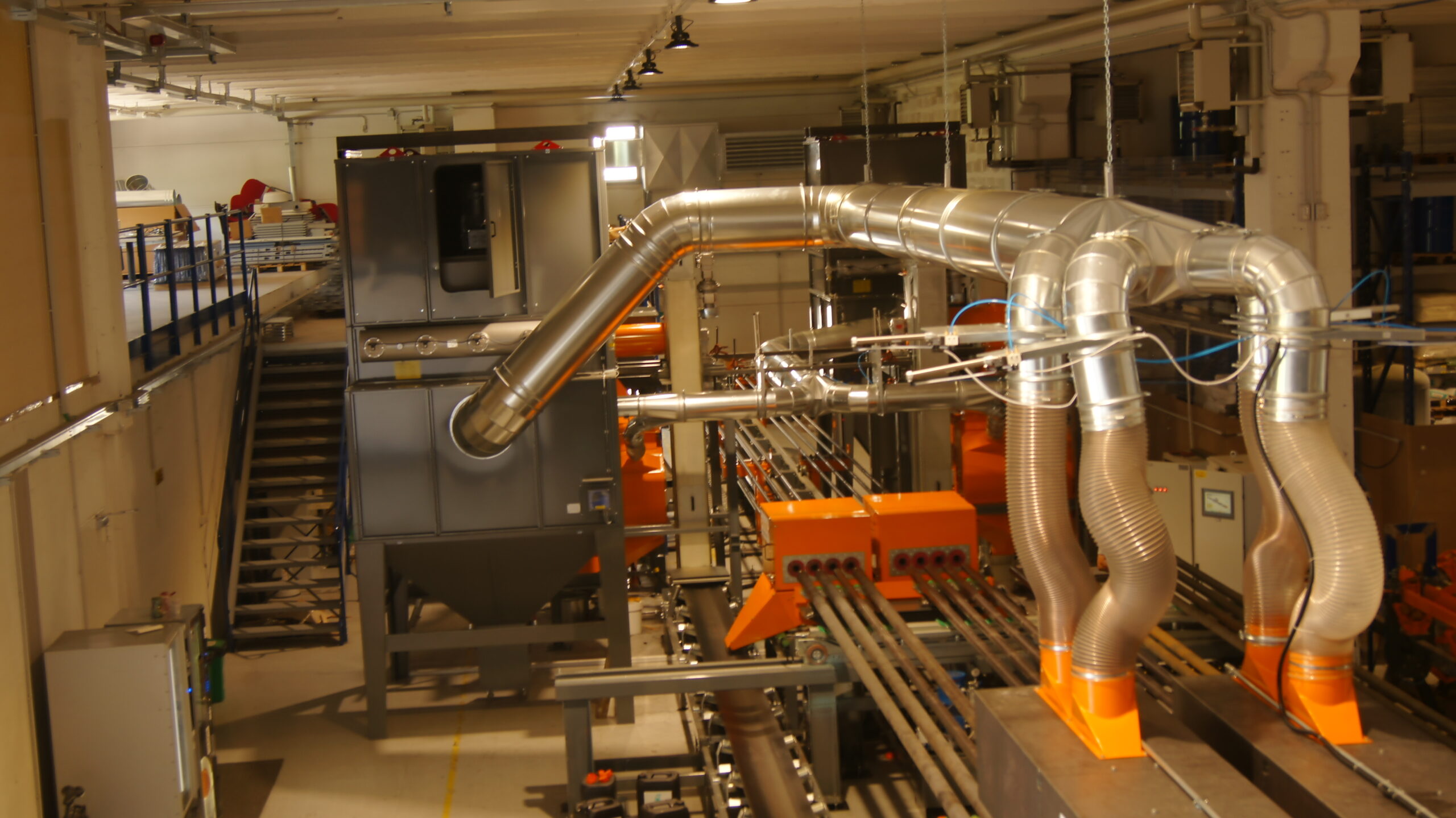

We are introducing our innovative inner pipe blasting machine designed to provide exceptional cleaning and roughness to pipes with ID ranging from 20 to 200 mm and flexible lengths from 3-12 meters.

Our machine operates 24/7, ensuring your pipes are always in top-notch condition. The blasting process is complete with the easy installation of our hollow blast or blowing nozzle on the lance, allowing for a thorough cleaning process. Our machine’s “train moving system” is a game-changer, facilitating flexible and efficient processing of pipes with varying diameters.

You won’t have to worry about any pipe being too big or too small. Our control system is integrated with our line coating production, providing a coordinated solution and allowing you to achieve the best results in the least amount of time.

SURFACE PREPARATION

Abrasive material

Abrasive material

Pressurize blasting

Pressurize blasting

Surface preparation

Surface preparation

Cleaning equipment

AMPP standard

Control software

Our machinery are top-notch technology for an integrated and automatic line where steel need to be protect.